The efficiency, accuracy, and detail of Scan to BIM technology

Auld & White Constructors is dedicated to continually providing innovative solutions for our clients.

One of the newest technologies that the AWC team is incorporating is Scan to BIM. This 3d laser scanning allows the team to efficiently, and with a high level of detail, document existing project conditions. This technology helps remove a large degree of human error from the traditional as-built documentation process. Additionally, it allows data to be collected in a much shorter period of time. For projects like the adaptive reuse of the Baptist Convention Building (218 West Church Street) and Federal Reserve Building in Downtown Jacksonville, this technology is instrumental for providing accurate conditions to meet the demanding schedule milestones.

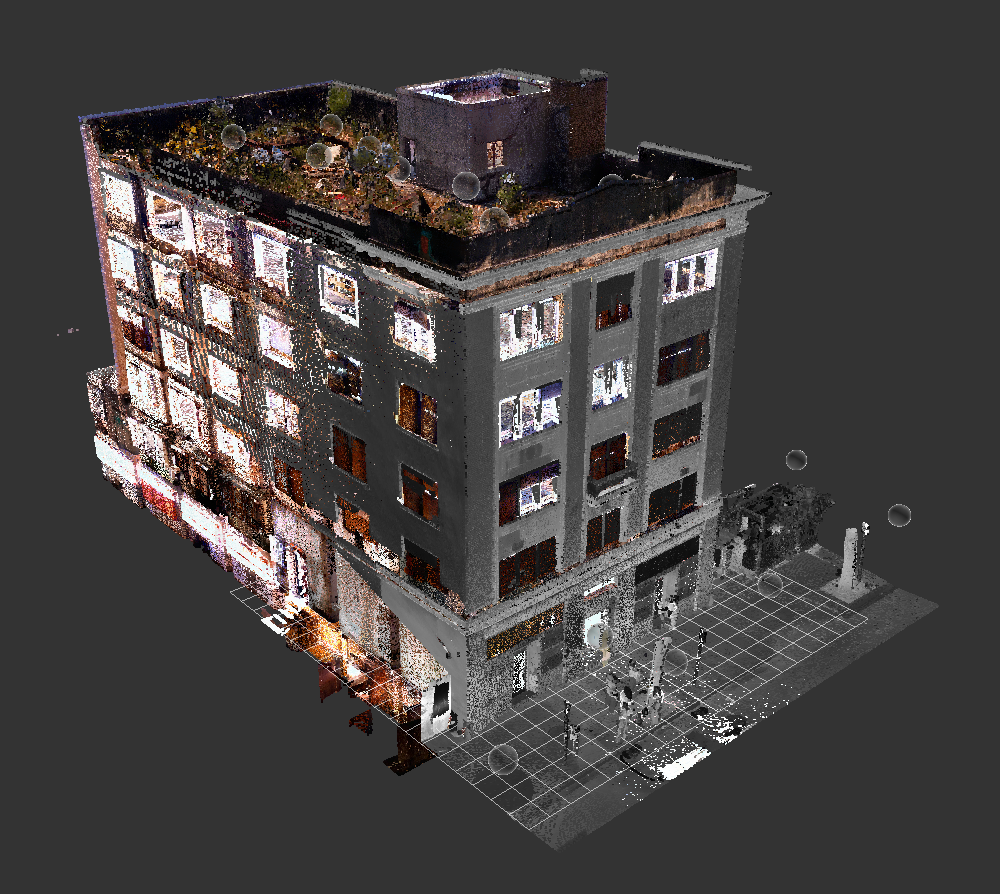

The 3d laser scanning system pictured above takes a complete 360-degree view of its surroundings. As it is running, it takes thousands of measurements, from a single point, with its rotating laser. These measurements are then converted into thousands of points in space creating a “Point Cloud” around the scanner.

By moving the scanner to several locations around the building, multiple individual point clouds are created, then stitched together to form a complete picture of the building. High-quality 360-degree photos can also be taken and overlayed on the point cloud allowing for precise measurements to be taken from any point in the picture.

Once all of the individual scanned point clouds are combined. The entire building is visible.

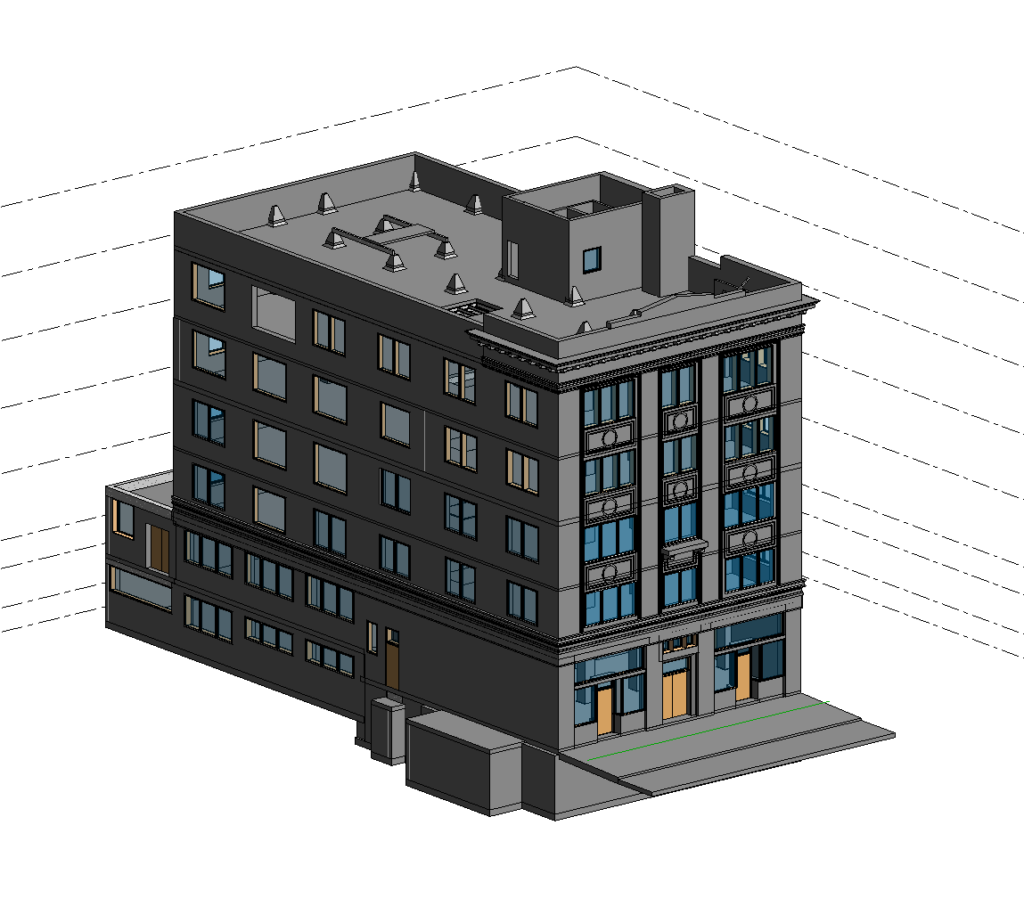

From here the point clouds are converted from millions of individual points into solid objects within BIM Modeling software, such as Revit.

The completed model of the existing building is then used as a framework for planning and coordination purposes as the new components (walls, ceilings, plumbing, ductwork, etc.) are modeled. This allows for conflicts to be discovered and resolved before any work is done onsite. The completed model is then converted into drawings to be used in the field indicating the exact location of the various building components to ensure everything fits and functions as intended. This reduces installation time and minimizes rework onsite resulting in labor and material cost savings.